Design Features:

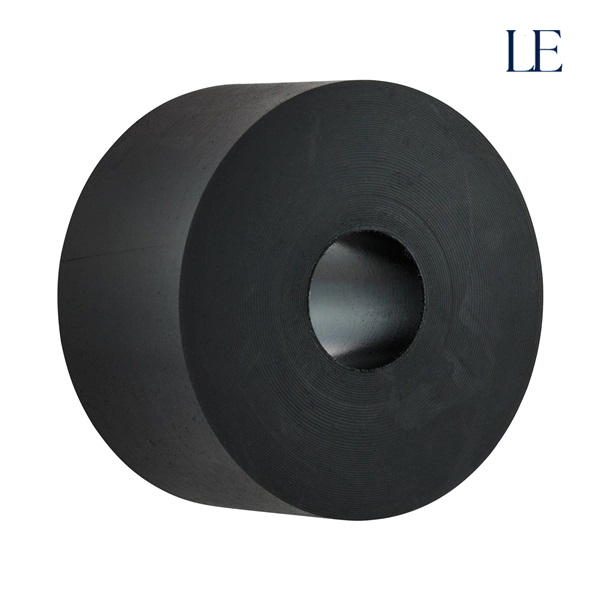

Surface Texture: The outer surface of the rubber roll can be smooth or textured. Textured surfaces, often with a patterned or patterned finish, can enhance the polishing process by providing better grip and distributing polishing compounds more evenly.

Diameter and Width: Rubber rolls come in various diameters and widths to suit different polishing machines and stainless steel parts. The diameter might range from a few inches to several feet, while the width can be customized based on the application and machine specifications.

Hardness and Flexibility: The hardness of the rubber is carefully selected to balance flexibility with durability. This allows the roll to conform to the surface of the stainless steel while maintaining enough rigidity to provide effective polishing.

Functionality:

Polishing Action: As the rubber roll rotates, it applies pressure to the stainless steel surface, often in combination with abrasive compounds or polishing agents. This action helps to remove surface imperfections, scratches, and oxidation, resulting in a smooth and shiny finish.

Surface Conformity: The rubber’s flexibility allows it to adapt to the contours and irregularities of the stainless steel surface, ensuring a consistent polish across complex shapes and surfaces.

Heat Resistance: The rubber is designed to withstand the heat generated during the polishing process without degrading, ensuring reliable performance and longevity.

Applications:

Surface Finishing: Used for achieving various levels of surface finish, from coarse to mirror-like, depending on the requirements of the stainless steel product being polished.

Versatility: Suitable for a wide range of stainless steel items, including sheets, coils, tubes, and other components.

Maintenance and Longevity:

Durability:Rubber rolls are built to be long-lasting, but they do experience wear and tear over time. Regular inspection and replacement are necessary to maintain optimal polishing performance.

Care: Proper maintenance involves cleaning the roll regularly to prevent build-up of debris or polishing compounds that could affect performance. Additionally, ensuring the roll is correctly aligned and balanced in the polishing machine helps to extend its lifespan.

In summary, a rubber roll used in polishing machines for the stainless steel industry is a crucial component that provides effective surface finishing. Its design, material, and construction are tailored to meet the specific needs of polishing stainless steel, ensuring high-quality results and prolonged performance.

Our following Sizes :-

• 112 X 30 X 42

• 112 X 34 X 42

• 112 X 36 X 42

• 112 X 38 X 42

• 112 X 40 X 42

• 112 X 55 X 35

• 112 X 55 X 42

• 127 X 40 X 38

• 120 X 16 X 24

• 120 X 35 X 24

• 120 X 40 X 30

• 120 X 40 X 40

• 120 X 35 X 130

• 120 X 30 X 170

• 120 X 36 X 170

• 120 X 90 X 170

• 130 X 42 X 120

• 105 X 62 X 125

• 105 X 38 X 125

• 105 X 25 X 100

• 105 X 32 X 100 – 6205 Bearing – ( Single Bearing – Both Side )

• 105 X 32 X 100 – 6205 Bearing – ( Single Bearing – One side, Double Bearing – One side )

• 105 X 42 X 100 – 6206 Bearing – ( Single Bearing – Both side )

• 105 X 42 X 100 – 6206 Bearing – ( Single Bearing – One side, Double Bearing – One side )

If upper quotation given sizes are required, You can place us a trail order.

Note: – In case if required other sizes , we can customised them as well.